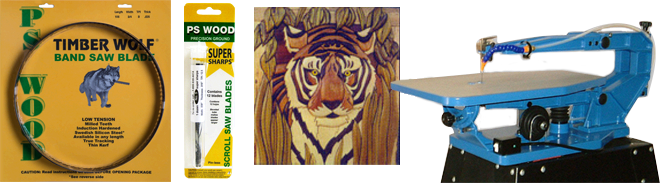

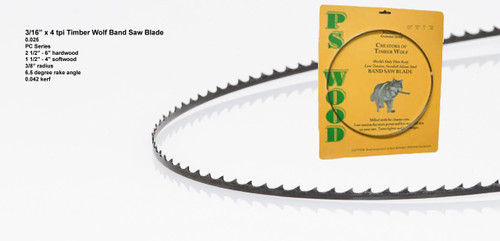

Blade Designation: Ripping and Crosscutting

Width: 3/8"

TPI (Tooth Per Inch): 4

Tooth Design: PC (positive claw)

Blade Thickness: .025

Kerf: .042

Tooth Hook Angle: 6.5°

Tooth Set Pattern: 5 Raker Set

Radius of Cut: 1 1/4”

Thickness of Work Material to be cut

Kiln Dry Wood: Hardwood 2 1/2” - 6" Softwood 1 1/2” – 4”

8 Reviews Hide Reviews Show Reviews

-

SHARP

Big improvement over the previous blade I tried. I'm a pretty new user on an entry level saw, and I needed to resaw a bunch of fairly thick pieces so I thought I should get a more substantial blade than the one that came with the machine, so I wouldn't have a bunch of wobble. Initially bought a little variety pack of 3 blade widths, so I'd have some options, you know? Seemed sensible to me, and they were a well known brand so I figured they'd be at least as good as the blade that came with the saw, right? WRONG. I tried the thickest of the 3 and it didn't cut anywhere near as fast as the original blade, it was so bad that I initially checked to make sure I hadn't put it in backwards. But I hadn't, and for my purposes keeping the cut straight mattered more than speed so I just dealt with it, feeding things slowly and backing off when I saw smoke (that should have been a clue but I genuinely didn't think it was possible for a blade to be as bad as what ended up happening). When I got done with my first (of three) passes through all 13 of the 18-inch boards, that crap blade had NO TEETH LEFT. It was just a slightly wavy piece of metal. I'm not really sure how it was still cutting (painfully slowly, but it WAS getting there eventually) Unbelievable. It wasn't even very hard wood, it was just 2x3 construction lumber. Anyway, I obviously had to go looking for a different blade to do the second pass with, and I was stumped at first because there isn't a very big selection out there for 60-inch blades, and what little does exist is all the same basic materials, all seemingly manufactured the same (cheap) way. What a godsend PS Wood turned out to be, letting me pick exact blade length. And it's definitely better made, it cuts SO MUCH FASTER than that other piece of junk! It just sails right through the wood like it barely notices anything's there. Definitely coming back to them when I need other blades. I realize I talked more about how bad the other one was than how good this one is, but that's kind of the thing. A good blade shouldn't be noticeable, it should just go through the wood and not be thought about much.

-

111" band saw blade.

Excellent

-

Timber Wolf Blades

This is the best product I have found for my needs in guitar lumber prep. A great company that stands behind their product!

-

Timberwolf blades

I’ve tried a lot of different blades for my bandsaw, these are by far the best They are the easiest to set up and usually track properly without any adjustment Long lasting sharpness and are very sturdy

-

3/8 blade 4pc

blade cuts great.

-

ps wood quality blades

i only use timber wolf blades. they are the best.

-

timberwolf blades

I have used these blades for ten years and have never had a problem. I use them for resawing and rounding green bowl blanks. I love these blades.

-

As usual, excellent blade from PS Wood

I have been using PS Wood blades for probably 20 years. I first saw them in the Woodworkers Show in Michigan. They are excellent and track so well. The thing that first attracted me to them was the demo where the cool-blocks were not even securing the blade for tracking. Since I moved to San Diego, they are not available locally, so I tried the Olson's from Rockler, and was not impressed. Finally, I decided to order online, and glad I did. You should try to get Rockler to carry. There is no Woodcraft store nearby.